How to Paint a Fiberglass Boat

But how do you paint a fiberglass boat? Which is the correct approach in the case of paint restoration? These are some of the questions most boat owners ask themselves.

So, in this article, we shall be discussing how to paint a fiberglass boat. To achieve an excellent finish, you will need to follow the right steps/procedure, carry out proper paint selection, paint preparation, paint application with an airless paint sprayer, sanding process, and smart final finish.

It’s important to know that selecting the wrong paint damages fiberglass coating, which may lead to a marine accident when cruising. Pay close attention to leakage points when painting the hull interior.

Details: How to Paint a Fiberglass Boat

It’s advisable to kill the engine, empty the gas tank, and remove all boat items when painting the boat since some boat paints are highly flammable. See Also: Removing Latex Paint From Metal.

a. Items needed

- Dual-action Sander material and foam brush

- Wax removing solvent and fiberglass primer

- Clean cloth pads and sandpaper

- Paint roller and covers

- 2-part urethane paint for boats and soap detergent

- Safety glasses/goggles and Clean piece of cloth

- Chemical respirator mask and hand gloves

- Clean water in a basin

See Also: Remove Latex Paint from Concrete

b. Steps and procedure to follow

The below-laid procedure helps significantly in the successful painting of fiberglass boats.

- Wear the eye goggles, hand gloves, and facemask to boost your safety during the painting process.

- Measure the boat from top to bottom and alongside (this measurement will help further in painting calculation).

- Polish the hull with sanding material to remove I inclusions and outer layer. Then, wash with soapy detergents to remove contaminants and clog that may be on the surface.

- Use dual action sander with 120 to 180 grit when removing a thick oxidation layer that may be formed on the hull surface. In case there minor oxidation, used 220 to 300 grit sandpaper on the longboard. You should not remove the gel coat entirely.

- Smoothen further the exterior and interior hull using fine grain sandpaper. You can run over the 320 to 400 grip sandpaper to achieve the perfect finish.

- Blow the surface gently to clean all the dust particles. Ensure the surface is dry and ready for painting. Mask section you intend not to paint to prevent rub rails during paint application.

- Apply a thin layer of undercoat paint that is compatible with the topside selected finish paint. You can use either a paintbrush or a roller. The undercoat is essential, especially when you are moving from dark paint to lighter final paint.

- After few minutes (as per manufacturer’s directions), gently rub/sand the surface with 300 to 400 grit sandpaper to smoothen the hull. Cover over the sanded area with extra undercoat where possible.

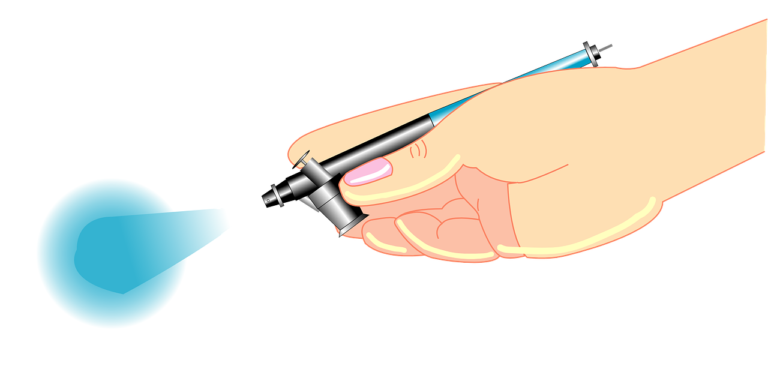

- Apply the paint (either by tipping or rolling) using a paintbrush until the surface is fully covered. You can opt for a spray machine too – this works excellently, especially for thick fiberglass material.

- Mask the lining for the anti-glossy area with antifoul section. Masking all patterns that you intend to achieve should only happen once the subsequent paint has dried completely.

- Wet the painted area to keep off dust and ensure you carry the painting process with 54F to 77F temperature range. The humidity shouldn’t exceed 81% to improve the drying process.

- Leave the painted fiberglass boat to drive for 24 to 48 hours. Do not test the boat until two weeks are over. This time allows the hull to harden and gain extra toughness that is water-resistant.

NB: Avoid sanding the final finish. When painting the hull interior, clear all other items and fill the leak points before paint application. Importantly, you should remove interior masking after complete paint curing has taken place.

See Also: Latex Vs Acrylic Paint

c. Paint selection

Paint selection is critical for a fiberglass boat. The boat is divided into two major areas; the upper topside and the bottom area that is usually submerged in water.

For the bottom section, you can comfortably use two-part polyurethane paint. The paint should have a high affinity for fiberglass material. This particular paint can also be used when restoring the painted surface. However, sanding and primer should precede the application process.

Use one-part polyurethane paint for the tip side and interior hull section. Following the primer or undercoat application, the rolling painting or spraying should be preferred instead. You can use enamel or alkyd paints as a finisher.

The 5-gallon container will be sufficient to cover the entire fiberglass boat painting (interior and exterior hull).

NB: Always follow the manufacturer’s advice when mixing the paint. See Also: Using Acrylic Paint On Metal?

d. Paint Application

To start with, dip the roller in paint. Ensure the roller soak just enough paint (prevents dripping). Run the roller fore and aft gently. Then, change the rolling direction and roll up and down until you cover the paint entirely.

You can smoothen the paint using a dry fine-hair paintbrush. Run the brush gently and tip over to cut off any paint that may tend to drip in the process.

The brush painting option is best used in a small area. It is tedious and doesn’t bring out a smooth final finish as compared to rolling or spraying. The tipping should be done gently. Use a wet sponge to squeeze the brush after use.

For the spray painting option, thin the paint as instructed by the manufacturer. Spray up and down, then fore and aft gently to achieve fine patterns.

Finally, lift the spray gun off before you stop the compressor to avoid the creation of drips on the surface.

e. Sanding Process

Sanding is a process that should be carried out before painting occurs. It aims at removing rough surfaces and molds that may be found on the fiberglass surface.

During the sanding process, select rough grains sandpapers (for starter) and fine grains sandpaper (when finishing).

Apply relative abrasive force to avoid removing fiberglass resin and avoid swirl marks that may be found on the surface.

Cut a long strip of sandpaper between 3 inches to 8 inches wide. The approximate sanding process may require 6 feet of fine and coarse grain sandpaper to complete.

See Also: Remove Oil Stains From Wall Paint?

f. Final Finish

To achieve a fine finish, blow cold air over the painted surface gently. This works best to quench and cure the paint molecules leaving the soft texture.

Besides, you will need to wet the surface with cold water to keep off the dust – most of the boat paints feature electrostatic properties that attract dust from surrounding quickly.

Avoid sanding the final painted surface unless you want to repair a particular area. Notably, it would help if you do not touch the painted area with free hands whatsoever.

g. Safety and precautions

Safety is paramount when painting a fiberglass boat. You will need to adhere to the following safety rules and precautions during the entire paint application.

- Wear protective gear when painting, i.e., face mask or respirator, eye goggles, overall, and hand gloves.

- Do not inhale paint directly – it may choke you.

- Carry out the painting process away from the fireplace – thinner used is flammable and may cause fire breakout.

- Do not mix two paint trying to boost performance – it may affect the fiberglass material or cause an explosive chemical reaction.

- Always check the expiry date of paint before you start preparation. Do not apply expired paint at all.

- Carry out a drop test before you commence applying paint to ascertain its stickiness on the surface.

- Don’t touch paint with bare hands. Rinse with cold water and soap in case you touch the paint. You can use turpentine or thinner to remove paint from your cloth or other fabrics.

- Keep unused paint away from children and pets.

See Also: Using WD 40 Remove Paint?

Common Problems Associated with Fiberglass Boat Painting

The following are some of the challenges associated with fiberglass boat painting.

1. Blisters

Blisters are tinny bumps and horizontal cracks that appear on fiberglass material the surface (interior or exterior hull). Blisters shield water of air particles that prolong with time, leading to the peeling of a fiberglass resin or paint coating.

Some blisters result from the boat’s collision with the water bodies’ materials or aquatic organisms on the surface.

Painting can cause blisters imaging when rub rails and runs are not finely finished. The thick paint fluid dries to form a solid drip line that peels off when it comes into contact with any abrasive force or with aging.

It would be best to repair the blister as soon as you notice its presence. Sand the surface finely and fill the blisters with the gel/primer before fine painting.

Avoid air-gaps when painting, as they are the primary source of blisters.

2. Fatigue

Fiberglass boat faces fatigue that comes from water wave forces and vibrations. The force strains exterior fiberglass resins and even causes internal compression due to unbalanced reactive forces when cruising.

Due to these forces, the paint coat weakens and peels off, leaving cracks or bear surfaces. Carry out paint restoration as soon as you note such occurrence.

Fatigue in fiberglass is an unavoidable occurrence. Therefore, frequent maintenance of your boat should be undertaken to identify such strained areas.

See Also: Using Mineral Spirits Remove Paint?

3. Delamination

Particular types of fiberglass boats have wooden material sandwiched between interior and exterior fiberglass surface. Delamination occurs when the middle wood breaks and destroys the surface orientation.

Besides, the surface paint may break and peel off due to non-uniform surface waves or reactive forces. Delamination may emanate from blisters, which allows water into the middle layer, thus weakening the wooden material.

The repair of delamination requires the stripping of the entire fiberglass surface and replacing it with new ones.

4. Stringer Damage

Stringer (this joists found at the deck of the boat) is often damaged due to collision with other water bodies or solid material. These forces weaken the stringer, which in turn causes non-uniform paint peeling off.

The base paint often comes out with fiberglass resin and weaken the boat. Indeed, continuous paint removal may lead to leakage – can capsize the boat.

Since every boat is subjected to wear and tear, you should check the stinger’s safety always and repair where necessary.

5. Warping

Warping occurs due to the weakening of the fiberglass core. The foam and plastic material that makes the fiberglass is subjected to strain, thus weakening its overall strength.

The fiberglass becomes susceptible to direct heat from the sun. The painted surface loses its stickiness-ability and starts peeling of abnormally.

In case you notice such occurrence on the boat, check the fiberglass strength. You can always replace the fiberglass substrate entirely and build the boat afresh.

Maintenance tips for fiberglass boat

Below are the best tips for proper maintenance of a fiberglass boat:

- Always keep your boat cleaning by cleaning with soapy detergents and clean water.

- Wax your boat yearly to improve the fabric service life.

- Avoid leaving your boat in the open field during winter –ice destroys the fiberglass

- Repair the stingers and reinforcement often to prevent caving in when cruising.

- The fiberglass boat should be a painter as soon as blisters and runs appear

- Spay your boat with antifoul solvent to improve service life and outlook

- Never carry an excess load with your fiberglass boat – it causes internal fatigue that leads to failure.

Conclusion

When painting your fiberglass boat, proper procedure/steps should be followed, as highlighted in this article. You will need to select the right boat paint, use the appropriate application method, and sand intensively before painting the entire surface.

Besides, you will need to carry out frequent boat maintenance to eliminate some failure problems and avoid overloading. Notably, the boat paint restoration process is the best practice to improve its service life.